Cyberism · Industrial Reliability

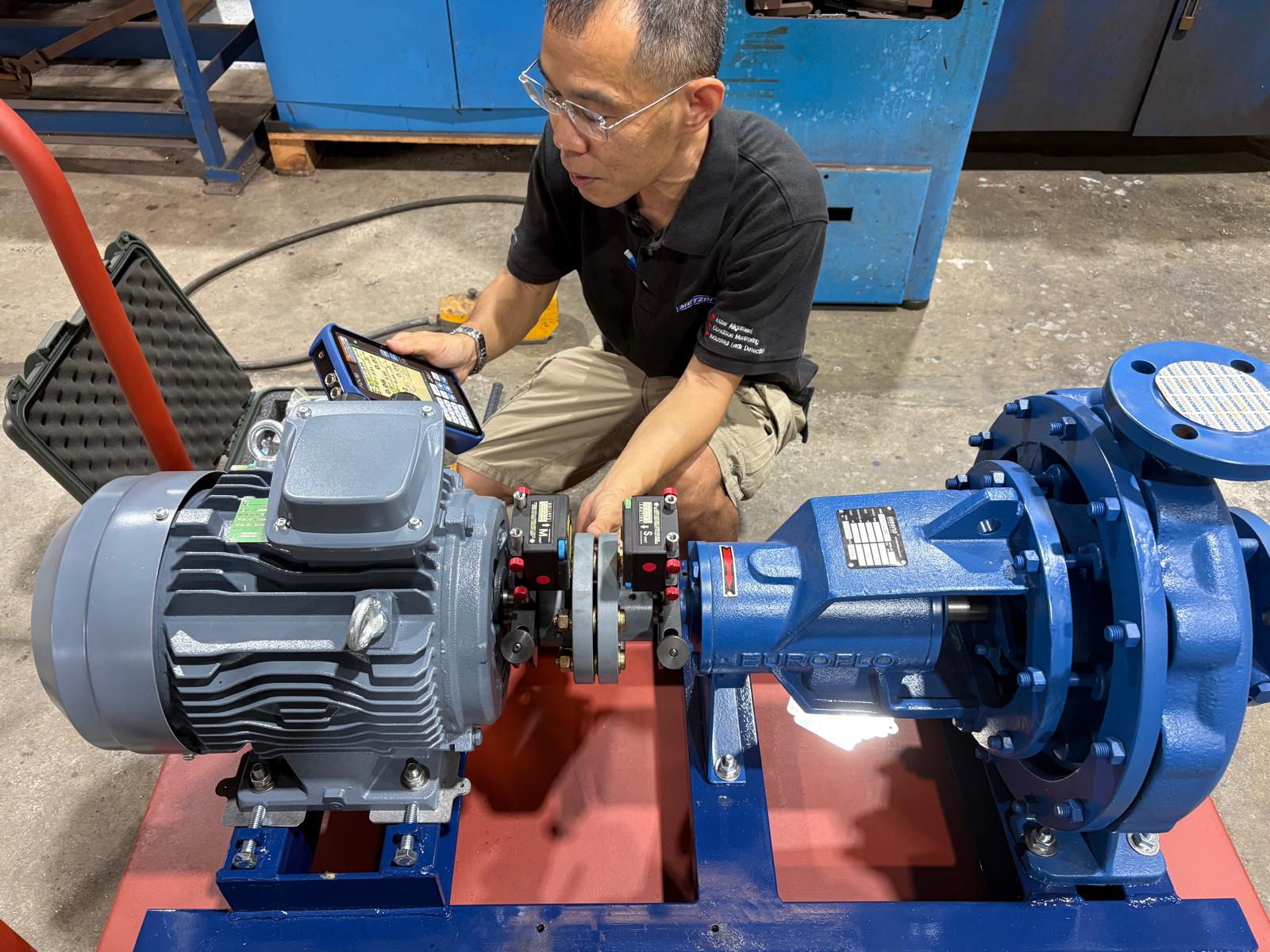

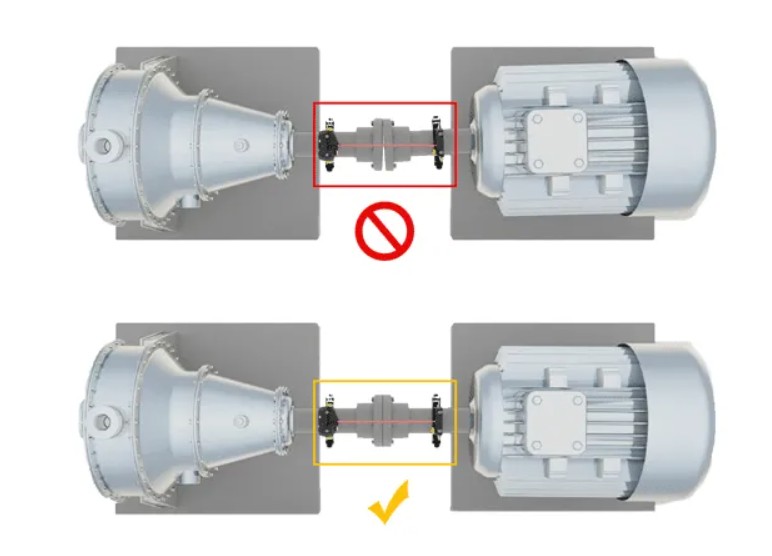

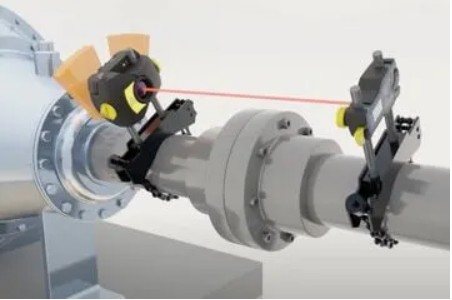

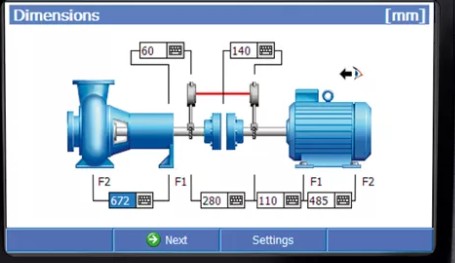

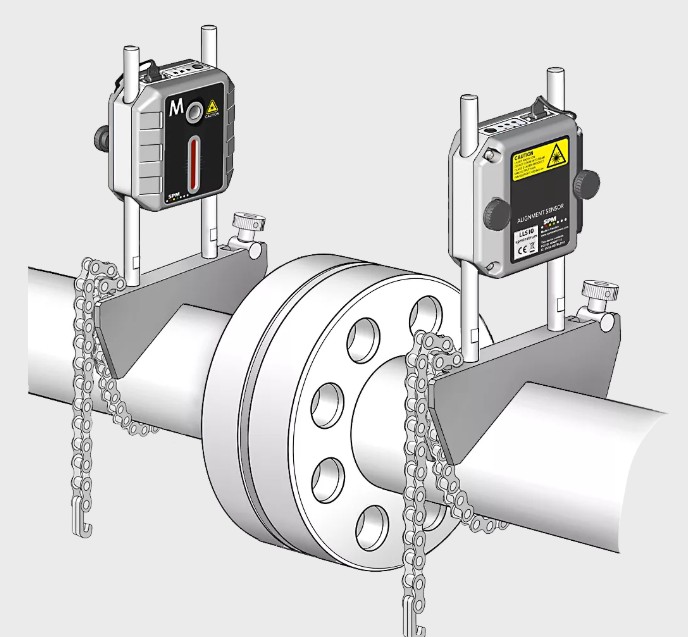

Precision Laser Shaft Alignment

CYBERISM delivers smart shaft alignment solutions for pumps, motors and rotating assets, combining industrial-grade laser hardware with IoT data and analytics.

Accuracy

±0.01 mm

Setup

< 5 min

Report

1-tap PDF